Campos EPC’s Engineering and Design Team offers decades of experience. Our team can provide an array of services to match our client’s needs ranging from scoping and feasibility studies through detailed design, construction, and commissioning support.

Our experience includes facility, transmission and midstream pipeline, distribution and utility design, valve automation, compressor and pump station, wellsite and gathering systems, renewable natural gas (RNG) and midstream gas processing. We also provide pipeline automation, controls, instrumentation, power delivery, conventional and renewable power generation, and manufacturing.

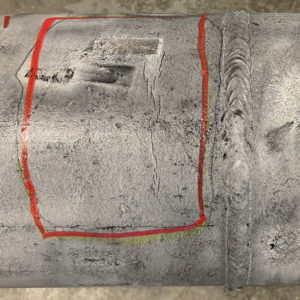

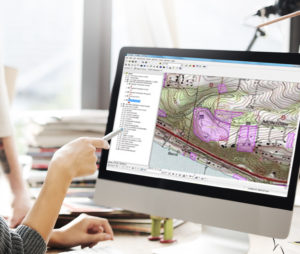

CEPC has a team of project managers, engineers, designers, drafters, estimators, control specialists, and construction personnel who have decades of experience in pipeline design and installation. Our team has design knowledge and expertise in all types of difficult and challenging terrain ranging from mountainous steep slopes and swamp / marsh wetlands, to highly congested urban environments.

Our solutions and expertise span all methods of construction, from replace-in-place direct bury through trenchless methods such as HDD, Jack and Bore, and Microtunnel. Our team of industry-leading specialists can perform all manner of required pipeline calculations in-house.

The CEPC team can carry out these projects to the level desired by our client, whether it is just providing the engineering design support for the project, or a cradle-to-grave type solution in which CEPC would handle all aspects of the pipeline design and project management work.

SERVICES

- Corridor Recommendation Study

- Route Selection / Feasibility

- New pipeline Design & Construction

- Pipeline Replacement Design

- HDD / Jack and Bore / Microtunnel Design

- Inadvertent Fluid Returns Analysis

- Geotechnical Evaluations for Trenchless Installations

- Fault Crossing Modeling and Pipeline Crossing Design

- Hydrostatic Test Design

- Launcher / Receiver Designs

- Valve Set Design & Modifications

- Interconnect Design & Modifications

- Environmental Review

- BMP Development

- Load and Stress Analysis

- Permitting (FERC)

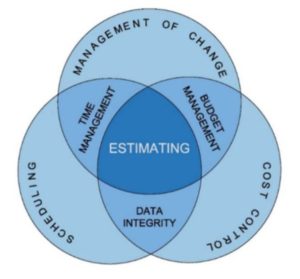

- TIC Estimating

- Turnkey Pipeline Construction

- Third Party Coordination (Survey, Geotchnical Drillers, SUE)

- Pipeline liquids handling evaluations

- Gathering system design and evaluations

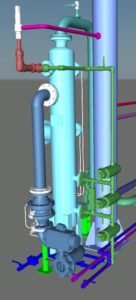

The CEPC Facilities Engineering group focuses on the engineering, design and project management of stations (large and small) and facilities containing rotating equipment and complex processes.

The Engineering group has experience developing projects from preliminary front-end engineering design studies through detailed engineering design including field support and commissioning. Our team is considered experts in the industry for M&R stations, city gate stations, compressor stations, pump stations, LNG facilities, propane facilities, and gas processing plants.

SERVICES

- Site Selection, Evaluation, & Scoping

- Valve Automation, RMV’s (ASV / RCV)

- Program Development

- Detailed Engineering & Design

- Metering / Measurement Design

- Control Valve & Regulator Design

- Filter / Separators

- Compressor Stations

- Pump Stations

- Gathering / Storage Facilities

- Gas Processing

- Biogas / RNG Facilities

- Equipment Specifications / Procurement

- FEED Studies / Project Scoping

- Pipe Stress Analysis (Caesar II)

- 3D Modeling / Site Scanning

- Field Engineering / Commissioning

- Process engineering & modeling of new and existing facilities

- Gas Quality and Interchangeability

- Capacity analysis of existing facilities

- Facility Studies

- Mechanical Integrity review and evaluation

- One off and custom projects

CEPC’s team of Civil and Structural Engineers has design expertise in all types of industries and locations. Our team has licensed engineers capable of working in most jurisdictions across the country to support any Civil project.

The Civil department is able to handle any project such as new/existing station design, hazard mitigation for exposed pipelines, locating and optimizing well pads, commercial and residential land development and any permitting support associated with a project. Our Structural team is well versed in taking any Concrete, steel, masonry or wood structure from a simple sketch to full fledged design to meet the client’s needs optimally and cost-effectively.

With an experienced team of designers, the Civil/Structural group is able to provide clients accurate 3D models for structures and graded areas to provide exact depictions of proposed work.

SERVICES

- Civil

- Roadway and Site Grading Design

- Hydrologic / Hydraulic Analysis and Design

- Site Dimension Planning

- Geological Hazard Mitigation Design

- Vehicle Accessibility Analysis and Optimization

- 3D Modeling and Animation

- Site Remediation Plans

- Structural

- Foundations (Deep / Shallow)

- Pipe / Cable Support Design

- Structural Steel Structure Design

- Concrete Structure Design

- Vaults

- Wood Structure Design

- Retaining Wall Design

- Pipe Stress Analysis and Vibration Verification

- Fabrication Detailing

- 3D Modeling and Clearance Optimization

- Pipe Bridges

CEPC provides Distribution Engineering and Design for both gas and electric Utilities and Municipalities. We are familiar with the unique requirements for the execution of utility distribution projects. We appreciate the intricacies involved in making such programs a success and understand the challenges associated with high volume programs in both urban and rural areas.

CEPC provides the management, organization, systems, and personnel that will deliver on all client expectations. This includes field data collection and customer communication, along with the preparation of the key engineering, permitting and project closeout deliverables.

SERVICES

- Main Replacement

- AMRP PE Design

- IP and Steel Design

- HDD Design

- Jack and Bore Design

- Public Improvement / Franchise Projects

- New Business

- Regulator / Farm Tap / Vault Design

- LP System / OPP Review

- Work Management Systems (SAP, WMIS)

- Permitting

- Federal, State, City, Local, Railroad, Environmental

- Jurisdictional Coordination

- GIS

- Data Management

- Mapping

- Design (BUD)

- Construction Support / Inspection

- Construction Support / Inspection

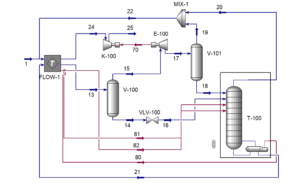

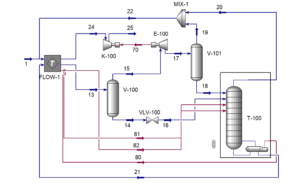

CEPC has the expertise to provide a variety of Process Engineering functions for facilities ranging from meter stations with control valves, field dehydration and stabilizations sites, wellpads, compressor stations and large processing plants.

CEPC Process Engineers have the experience to execute many different studies to help in the review of a facility that is a new build or an existing facility. CEPC Engineers can help get the most out of an existing facility or support the design of a new state-of-the-art facility.

SERVICES

- Process Studies

- Flare studies

- Existing facilities that are looking to expand.

- Existing facilities looking at a capacity change.

- Recertification of a Flare Study to meet PSM requirements.

- Design and evaluation of a new flare system.

- Debottlenecking/Capacity Studies

- Process Optimization Studies

- Process Model updates

- Process Operation Troubleshooting

CEPC has experience with several major Water / Wastewater Agencies providing PMO and PM Services, Engineering, Pipeline Integrity, and Master Planning, and Construction Services.

SERVICES

- Water / Wastewater Pump Station

- Instrumentation and Control

- SCADA Programming

- Pipeline Assessment / Integrity Management

- Primary and Backup Power – Turbine and IC Systems

- Cathodic Protection

- High Voltage Electrical Systems

- Natural and Digester Gas Piping

- Foundations and other Structural Facilities

CEPC provides technical Engineering, Procurement and Construction support in the Liquefied Natural Gas market. Our experience covers all aspects of these facilities including metering, pretreatment, liquefaction, storage, vaporization, and truck loading/unloading.

Our experienced multi-disciplinary team of engineers provide unique solutions for your LNG projects from feasibility analysis and conceptual designs to commissioning and startup. Additionally, our experienced team can assist you with thorough compliance assessments of existing facilities, FEED Studies, HAZOP/HAZID, permitting support, fire protection support, control system automation, and O&M manual development.

CEPC has consistently exceeded all client expectations, and LNG is no exception. Our experts understand the unique requirements for the execution of LNG projects.

SERVICES

- Project Feasibility Analysis

- Front End Engineering Design (FEED)

- Multi-Disciplinary Engineering & Design

- Civil / Structural

- Process

- Mechanical

- Power & Controls

- Process Hazard Assessments (PHA) – HAZOP/HAZID

- Permitting Support

- Procurement Support

- Construction Management

- Commissioning & Startup Support

- Regulatory Support – FERC / PHMSA / Local & State Authorities

- Liquefaction Technology Selection Support