Hydrogen Blending Solutions

With a continuing push for more renewable energy options and reduction of greenhouse gas emissions, hydrogen-based energy solutions have emerged as significant contenders. The issue for hydrogen, however, is the question of effective production, distribution and compatibility with existing infrastructure. Implementing entirely new distribution pathways would be a tremendous and costly task, which has led to the interest of Hydrogen blending into Natural Gas pipeline systems. This would allow for easier distribution within already established systems.

What then are the potential issues that could be faced with hydrogen blending? The total amount of hydrogen gas that can be blended into natural gas systems without adverse effects to existing distribution systems and end use systems must be determined, as well as any potential safety hazards considered and planned for.

There is also the issue of how to produce Hydrogen gas efficiently and cost effectively. Typical methods of H2 gas production often require the use of non-renewable energy sources, which cancels out the benefits of using H2 gas as a clean energy source.

Electrolysis is a good solution. Combining renewable energy sources such as wind and solar with electrolysis systems will produce Hydrogen gas without greenhouse gas emissions. This not only solves the issue with H2 gas production, but also assists in overcoming the variability of some renewable energy sources.

To support the safe and effective implementation of H2 gas for our clients, Campos EPC, along with our partners, is supporting hydrogen design and testing projects along with determining safe operating metrics for Hydrogen blending in natural gas pipelines.

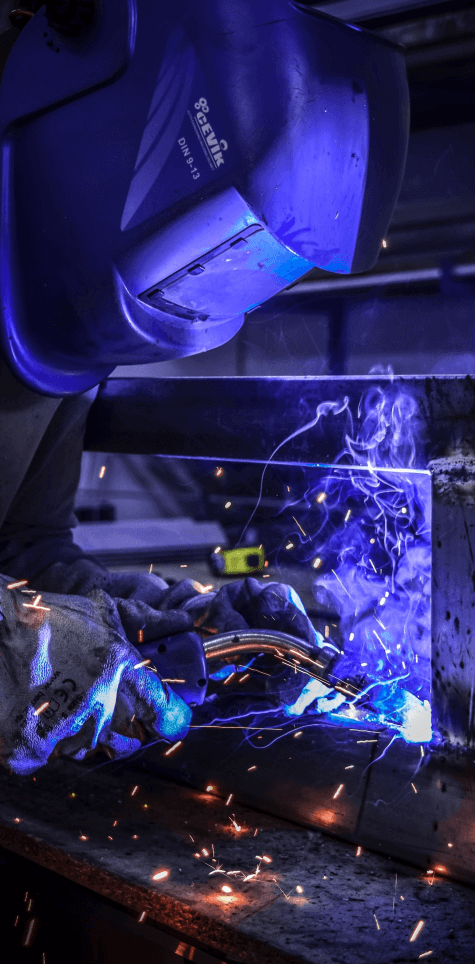

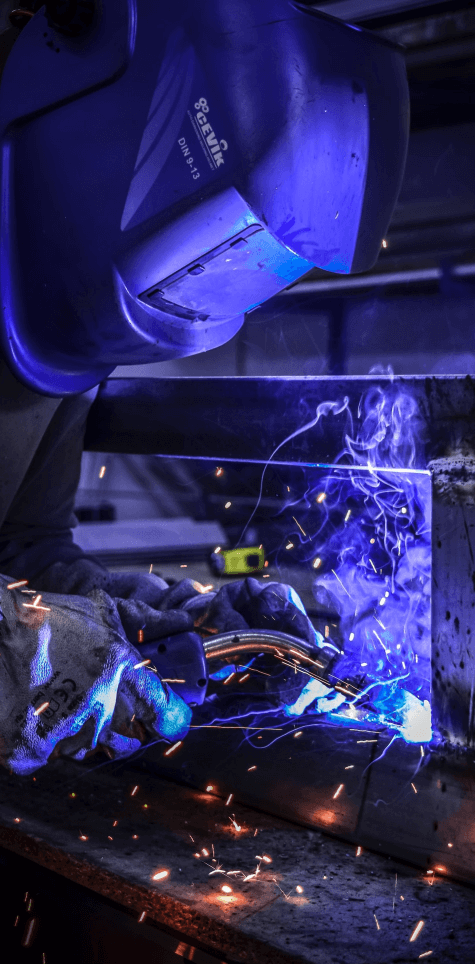

We have designed a phased timeline on how this can be accomplished within already established systems to assist in project planning and preparation. We have also designed modular hydrogen blending, injection and measurement systems installed in natural gas testing facilities to study impacts to distribution systems in a controlled environment.

For any Hydrogen blending needs, we are able to provide detailed engineering support for mechanical, electrical, and controls scope, as well as a thorough review of hydrogen specific safety protocols, procedures, equipment spacing, and materials selection.

We also support end-user appliances testing, equipment testing, and combustibility analysis. Furthermore, we have researched and established connections with electrolyzer manufacturers, allowing us to plan and build complete hydrogen production and blending systems.

For assistance with any Hydrogen Blending programs and projects, please contact Andrew Duin at andrew.duin@camposepc.com.